Powder metallurgy

The Active-nano company develops technologies for the production of nanostructured composite powders. The mechanical alloying processes are used in the powder metallurgy for the production of thermally stable and heat-resistant alloys. The dispersion-strengthened alloys are applied in the aircraft industry, space industry, automotive industry, as well as in the production of turbines and electric contact materials.

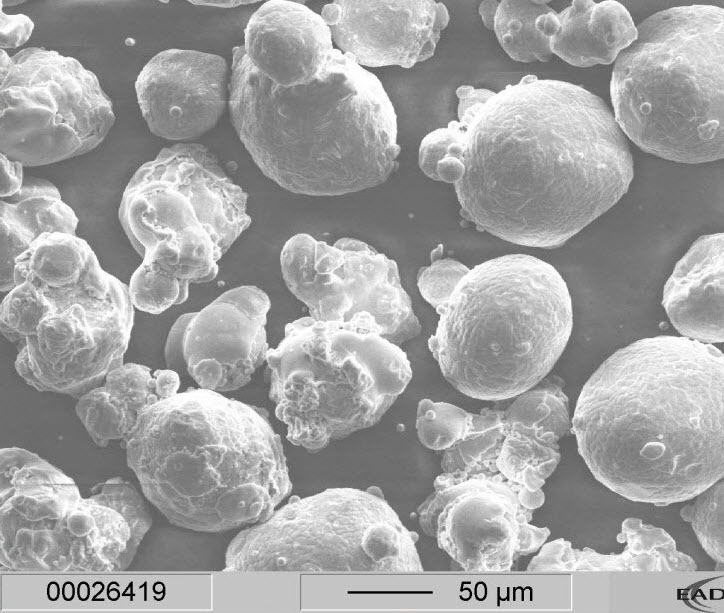

An important role in the development and creation of materials having tailored properties belongs to the powder metallurgy. This method is nowadays used for the production of a wide range of the powder and composite materials. The idea of powder technology is the usage of initial raw materials in the form of powders (metallic and non-metallic). These powders are formed into metal parts having predetermined sizes and exposed to the thermal treatment at the temperature lower than the main component melting point. In the case of mass production this method is notable for: • high output, • economic efficiency, • it is a wasteless process (reduces the material losses down to 5 %), • allows one to obtain items having high accuracy of sizes, • gives possibility to create new materials having wide range of properties which are in some cases unique and can not be obtained by other methods. The first operation in the powder metallurgy standard technology is the production of powders and/or the preparation of the charge, i.e. mixing of the different powder components of the required content. Metallic powders represent the assemblage of metal, alloy, or metal-like compound particles contacting each other but not connected to each other. Alloying compositions (ligatures) are auxiliary alloys used to introduce the alloying elements into the composition of main metallic alloys to provide them with particular physical, chemical, or mechanical properties. Metallic powders are characterized by the sum of physico-chemical and technological properties. Chemical properties of a metallic powder include its chemical and phase composition, gas saturation, pyrophorisity, toxicity, explosion hazard. The chemical composition is estimated

by the content of the major metals, alloying elements, admixtures, and gases. Non-metallic inclusions are mainly the oxides of major and impurity elements. Powders’ characteristic feature is their gas saturation. Gases can be adsorbed both on the surface and in the pores of powder particles. As the particle size decreases the intensity of the powder interaction with the ambient medium increases. This leads to the increase of gas saturation and metal oxidation degree. The admixtures limit content in powders depends on their acceptable maximal quantity in the final product. Important physical properties of powders include density, specific surface, shape, size and micro-hardness of the particles, functional properties (electrical, magnetic, optical, and others). Powders used in the powder metallurgy field have high surface area and high content of surface and bulk defects. This feature determines their behaviour during the following treatment and distinguishes them from the bulk materials of the identical composition. The powders’ particle size is mainly in the range from 0,5 to 500 mcm The main technological properties of powders are the following: packed density (bulk specific density), the angle of natural slope, fluidity, compactibility, and sinterability. Russian industry produces a wide range of powders consisting of such metals as iron and its alloys, nickel, copper, cobalt, aluminium, titanium, tin, zinc, lead, magnesium, tungsten, molybdenum, tantalum, niobium and others, alloying compositions and modifiers. Powders used in the modern powder metallurgy represent the products with high added value whose properties are greatly influenced by the production method. Scientific investigations allowed to create some novel processes for the production of metallic powders differing in granulometric, chemical, and phase composition, and also in particle shape and microstructure. At present, the developments of management methods and scientific principles for the creation of structure and properties of nanocrystallite composite powders having various functional purposes and crystallite size less than 100 nm are performed. APPLICATION OF THE POWDER METALLURGY Metallic powder materials are used practically in every technical field and the sphere of their application expands continuously. Anti-friction materials allowed one to increase the reliability and the life cycle of the friction units, and to decrease the costs substantially. The development of such materials consisting of the porous metallic matrix filled with solid lubricants made possible their usage in facilities where liquid lubricants are inadmissible, for instance in the food processing industry and at high temperatures. The porous powdered materials are widely used in the friction assemblies, filters, heat pipes, seals. Electro-technical materials, contacts, soft magnetic materials, hard-magnetic materials, instruments for electro-erosion treatment, spot welding, stitch welding are nowadays more and more widely used in electrotechnology, power generation, scientific instruments manufacturing, automatics, telemechanics, radio electronics and other fields. Powdered constructional materials are the most widespread products of the powder metallurgy. These products are used not only in technics but for instance in medical applications such as implants for dentistry and orthopaedics. Thermally stable, heat-resistant and composite alloys are responsible for the development in such modern technical fields as aviation, rocket and space technology, chemical machine-building, where the exploitation of machines and aggregates is impossible without ensuring special properties. For the needs Materials used in the modern nuclear power generation are exposed to extreme mechanical and thermal loads along with the radiation exposure. They are used as constructional and absorber materials, as delaying elements and also as fuel. They include materials obtained by powder metallurgy along with other kinds of materials. The Active-nano company develops the technologies of mechanical alloying basing on the use of the planetary mills. The following literature was used as a source: 1. V.N. Antsiferov “From the Egyptian Pyramids to the Space.” // Soros Educational Juornal, 1996, No 5, pp.109-114. 2. V.V.Boldyrev “The Application of Mechanochemistry in the Creation of the ”Dry” technological Processes” // Soros Educational Juornal, 1997,No12, pp.48-52. 3. V.G.Pushin “The Novel Promising Nano-Crystalline Materials: Technologies, Structure and Properties.” // “Phase and structural transition in steels” // Collection of scientific papers, Issue 2, 2002, pp.291-299 (in Russian) 4. Smetkin A.A., Yarmonov A.N. “The Mechanical Activation Conditions Impact on the Characteristics of the Powders Based on Titanium” // The Problems of the Modern Materials and Technologies. The Bulletin of PSTU, 2001, No 7, pp.48-54. (in Russian) 5. Butovskiy I.E. “The Synthesis of Copper-Tin Amalgams” // Proceedings of Universities. Non-ferrous metallurgy, 2003, No 1, pp.43-45. (in Russian) 6. Lyahov N.Z., Panin V.E., Dudina D.V., and others “The Development of Constructional Materials Basing on the Nano-Composite Powders” // Physical mesomechanics, 2003, Vol.6, No 2, pp.63-76. (in Russian) 7. N.G.Zaripov “The Technological Principles of the Powder Metallurgy”, the textbook for the students specializing in the materials science in machine building (speciality No 1208), Ufa State Aeronautical Technical University http://nayilz.narod.ru/PorMet/index.html 8. S.D.Shlyapin, A.A.Il’in, B.A.Kolachev, T.G.Yagudin “Mechanical Alloying of Powders for the Binders of Diamond-Bearing Composite Materials” // Proceedings of Universities. Non-ferrous metallurgy, 2003, No 4, pp.52-53. (in Russian) 9. Yu.V.Kuzmich, I.G.Kolesnikova, V.I.Serba, B.M.Frejdin “Mechanical Alloying” Apatity, The Publishing House of the Cola Scientific Centre of RAS, 2004, p.179. (in Russian)

|

Active-nano (Andrey V. Petrov)

of these fields, the refractory alloys and compounds were created. The powder metallurgy methods are in many cases the only suitable methods to obtain such materials. The refractory solid oxygen-free compounds and materials based on these compounds (carbides, borides, nitrides, silicides, and others) are in use in many industrial fields, for instance in tool-making industry owing to their unique properties. Hard metals are among the most important wide-spread powder materials. During the production of such materials the possibilities of the powder metallurgy are completely used. These possibilities include production of composite materials from the components having extremely different melting points, attainment of the unique complex of physical-mechanical properties, wasteless technology. Hard metals are used in tool-making industry, drilling, and during the shaping with the use of pressure.

of these fields, the refractory alloys and compounds were created. The powder metallurgy methods are in many cases the only suitable methods to obtain such materials. The refractory solid oxygen-free compounds and materials based on these compounds (carbides, borides, nitrides, silicides, and others) are in use in many industrial fields, for instance in tool-making industry owing to their unique properties. Hard metals are among the most important wide-spread powder materials. During the production of such materials the possibilities of the powder metallurgy are completely used. These possibilities include production of composite materials from the components having extremely different melting points, attainment of the unique complex of physical-mechanical properties, wasteless technology. Hard metals are used in tool-making industry, drilling, and during the shaping with the use of pressure.